Battery Servicing

All batteries require regular care and maintenance including cleaning.

Battery Testing and Reporting

If you are having issues with batteries, including battery run time issues, we can complete a test on the battery and provide a report on battery cell condition, electrolyte specific gravity and cell voltages. At ITS Forklifts, we are capable of in-house testing of batteries and can complete a capacity test to determine the battery’s state of health and the remaining economic life of the battery.

Battery Regeneration

Battery Replacement

At ITS Forklifts, we offer new replacement and additional batteries from worldwide brands – Century Yuasa, GNB, Exide, Hawker, Douglas and Enersys. We can supply batteries for all forklift’s brands. When your battery is finally dispensed, ITS Forklifts will dispose of your old battery in an environmentally safe manner. Battery Chargers and Charging Systems. We offer a range of battery charging options and charger profiles dependent on your site requirements. AC input voltage, duty cycles, and environmental factors are considered. ITS Forklifts offer rapid battery charging – again dependent on your site requirements and duty cycles.

Battery Management Systems

Along with battery chargers, we offer battery changing systems and equipment. This can be monitored with a battery queuing system and individual battery ID’s whereby the next battery in line may not be the battery that has finished its charging cycle first but the battery with the coolest temperature. This ensures that all batteries receive equal usage and helps to promote a first in – first out battery rotation. In addition to the charger display, the next battery available can also be viewed on a remote terminal display.

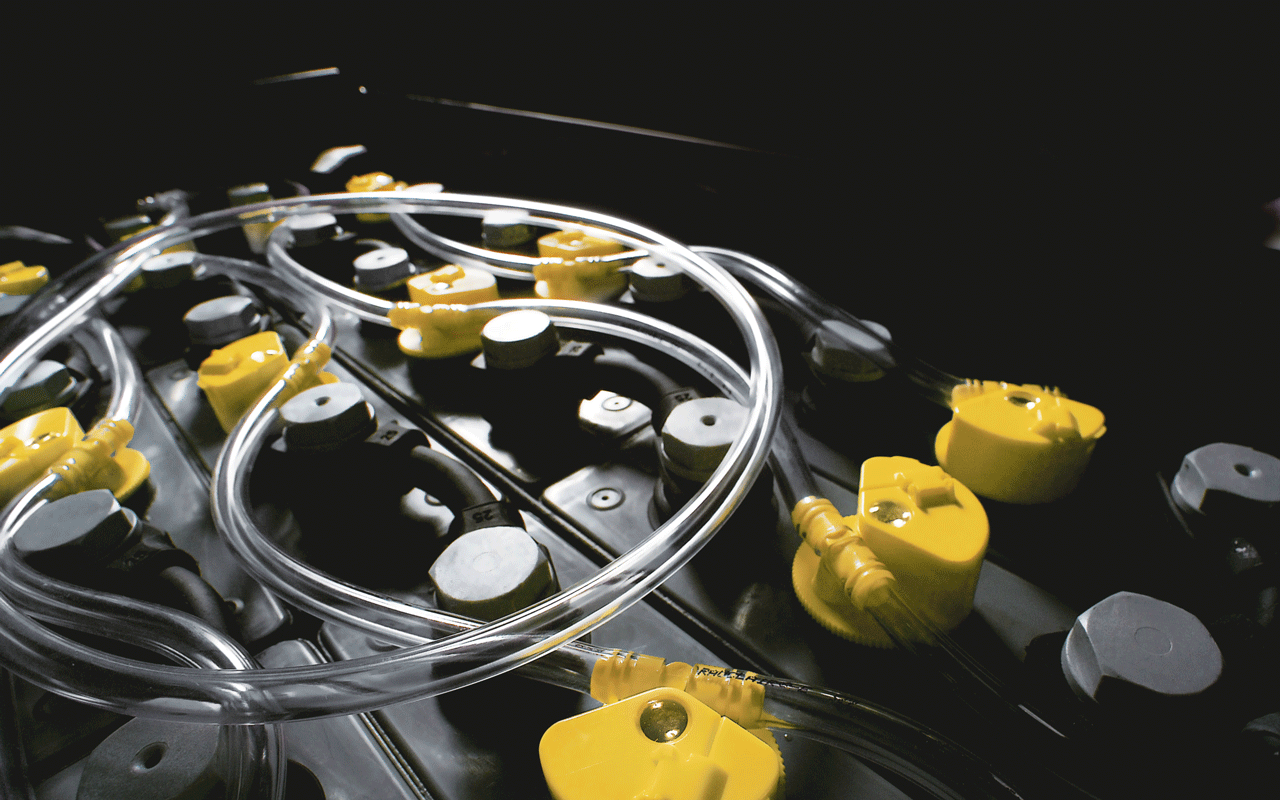

Battery Watering Systems

Electrolyte Level Sensor

The electrolyte level sensor measures electrolyte levels on a battery/cell and provides a visual display of whether the electrolyte is at, above or below the minimum level. This will provide you with the peace of mind your batteries are healthy.

Single Point Watering SystemThe single point watering system has many features including:

Various floats are available to suit different battery types. You have the luxury to choose between gravity feed/electronically controlled fillings.

As battery regeneration technology has improved it is now a popular and cost effective solution. It is estimated that 80% of batteries breaking down and losing capacity are sulphated, but can be restored with the right equipment.

Industrial Truck Sales has invested in Energic Plus battery regenerator technology and can successfully remove sulphation using its electrical high-frequency pulsation process. This process restores the battery capacity, giving you the ability to reuse old and sulphated batteries. You can also use the battery regenerator for annual maintenance to strongly prolong the lifespan of your batteries.

- Combination of battery discharger and battery charger all in one

- Detailed test reports

- Expanded lifespan of batteries

- Quick regenerations

When a battery’s energy charge is drained and needs to be charged during normal working cycles, sulphate crystals gradually build up on the electrodes, preventing the battery from effectively delivering current. The crystals in effect suffocate the battery. This lead sulphate increases internal resistance and decreases the specific gravity of the electrolyte. The process of sulphation build-up is unavoidable. Worse yet, after 3-4 years the process accelerates substantially.

Batteries sulphate due to a mix of reasons:

- The battery was inactive for too long

- The battery was discharged too deeply

- The wrong charger was used

- A bad cell was left untreated

- The battery has reached too high/low temperatures

- The charge cycles were disrespected

- The battery was charged when it had not reached 80% depth of discharge (DOD)

With Jungheinrich Snap Fit – costly battery mistakes can be heavily reduced. Fast and safer.

Lithium-ion technology from Jungheinrich

Lithium-ion technology from Jungheinrich

Li-ion batteries are revolutionising the market for electric industrial trucks. And with good reason. High-performance energy cells score over traditional lead-acid batteries with world-leading performance, fast charging times and zero maintenance. Our li-ion batteries ensure continuous operation and thanks to their long service life, you get plenty of use out of them. On top, we offer you a 5-year guarantee on li-ion batteries. Switch now and easily outrun your competition.