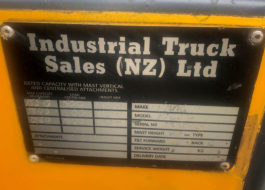

Equipment Details

Jungheinrich Turret Truck EKX 515

- Vehicle Overview

- Technical Specifications

We have a range of pre-loved Jungheinrich EKX turret trucks for sale or hire.

Models: EKX 515 and 515k

Capacity: 1,500 kg

Lift height h3: 8,250 - 10250 mm

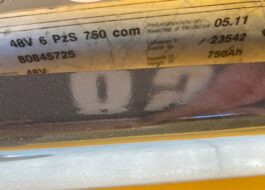

Battery voltage: 80 V

Battery capacity: 620 - 775 Ah

Please call us to discuss your project and application.

P.O.A

A range of feature and options are available dependent on your application.

Standard feature for the Jungheinrich EKX 5 series turret trucks as below.

Infinite control of hydraulic motor speed for high efficiency

- Hydraulic pump motors only run at speed required to complete requested action so no energy is wasted.

- Powerful, efficient forklift motors run cooler for even greater efficiency.

- Seamless operation of all lift truck functions together.

Integrated Jungheinrich personnel protection system (PPS)

- Optionally available, factory installed and integrated into the lift truck’s electronic control system/CAN-Bus.

- Senses presence of pedestrians in working aisle and alerts operator; slows and/or stops the forklift as necessary.

Ergonomics and comfort

- Generously dimensioned entrance into the lift truck's operator cab.

- Large footwells and adjustable knee supports make room for a wide variety of operator sizes.

- Excellent visibility towards the load with low mounted turret and clear view masts.

- The seat is spring cushioned, adjustable and foldable to ensure full-shift comfort.

- Electrically adjustable operating console with color display.

- Soft-key pad (softkey) with number block.

- Lift truck performance can be set for each specific operator or can be selected by the operator to suit the needs of the load.

- Switchless, two-handed operating concept for reliability.

- All hydraulic functions have end of travel dampening for smooth operation and maximum load stability.

Control and CAN-Bus system

- All functions are adjustable.

- Electronically controlled drive-wheel brake and electromagnetic, laminated, wear-free brake on load wheels.

- Active or passive stabilizers for maximum capacities to high lift heights (optional).

Commissioning and maintenance

- “Teach-in” process during installation “teaches” the forklift truck the exact configuration of the warehouse for maximum utilization.

- Integrated diagnostic system for remote maintenance via modem.

- Up to 1000 operating hour service intervals.

- Electronics with wear-free sensor system.

- Sealed drive unit with lifetime rated gear oil.

- Revolution counter on wheels with traction control and wear recognition on drive wheel.

Reliable operation – high utilization

- Robust and wear-free 3-phase AC motors require no down-time for maintenance.

- 70% fewer cables and plugs due to CAN-Bus.

- Extremely torsion-resistant mast for high residual capacities and low mast sway.

Additional equipment available

- Mechanical rail guidance.

- Inductive (wire) guidance for precise control in the aisle with no mechanical wear of components.

- Modular telescopic forks for multiple pallet dimensions.

- Comfort package “workplace” with workplace lighting, mirror and fans.

- Synchronized rotation of forks.

- Mechanical and electrical support for warehouse material flow management systems.

- Lift truck preparation for working platforms.

- Modular system for lift and travel stop as well as lift truck speed reduction.