FORKLIFT BATTERY TYPES.

The electric forklift industry relies on different battery types for power, and it’s important to know what makes each type stand out as the battery is the beating heart of any electric forklift truck. Discover the outstanding quality and top performance of the following types of forklift batteries for yourself:

Lead Acid Forklift Batteries

Sometimes referred to as wet cell batteries, Lead acid batteries are one of the most common in the forklift market.

The lead-acid batteries are available in standard models for easy and heavy-duty operations as well as with extended maintenance intervals for light and moderate tasks. You benefit from high efficiency at low prices.

Robust battery technology for maximum performance and reliability as well as high energy density – our sealed standard lead-acid batteries in 24, 48 and 80 volts are the perfect choice for easy to heavy-duty operations. Components include a battery case, cells, and cables, as well as a mixture of sulfuric acid and water. For best performance we rely on liquid electrolyte and the tested tubular plates technology. Due to the electrolyte-density of the pole terminals, the batteries remain long-term sealed, while being easy to service thanks to fully insulated bolt-on type poles and cell connectors.

Lead acid batteries need regular maintenance for top performance. Some charging systems may need specialised electrical work to support voltage demands. Wet cell batteries also need regular watering to maintain electrolyte levels. There are optional features like Electrolyte circulation that will increase efficiency: Air pumped into the battery thoroughly mixes the battery acid. This poses the advantage that batteries can be recharged faster. And due to low water consumption, maintenance requirements are reduced. In addition, the optional centralized water filling system Aquamatik enhances the efficiency of the batteries.

Lead-acid batteries with extended maintenance intervals for light and moderate operations are available as 24, 48 and 80 volts versions. Optimized sheet alloys reduce water consumption, allowing for up to 120 cycles (charge/discharge) without water refills. The optional electrolyte circulation and Aquamatik also contribute to this effect.

Lithium-Ion Forklift Batteries

Lithium-ion batteries are growing in popularity for forklift use. While more expensive than wet-cell batteries, they offer many benefits in comparison. As a leading provider of li-ion technology, Jungheinrich have been developing this technology intensively for over ten years, for the best performance of your warehouse.

The main benefits from the advantages are:

- More constant voltage curve than lead-acid batteries thus reliably high performance.

- The increased efficiency in comparison with conventional technologies significantly reduces energy costs and CO2 emissions.

- Lithium-ion batteries are absolutely maintenance free and do not emit gas. That largely eliminates the costs of battery upkeeping, maintenance and infrastructure.

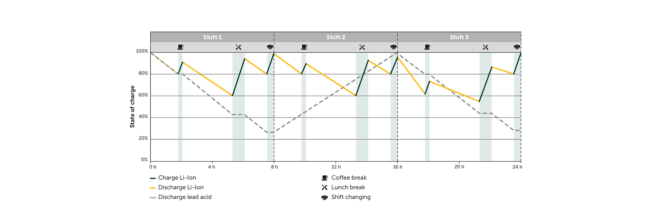

- Fast and opportunity charging during breaks and downtimes for a 24/7 availability of trucks and flexibility in your warehouse.

- Within 30 minutes of charging the 24 Volt battery absorbs 50 percent of its capacity. After 80 minutes it reaches its full charge status.

Typical charge and discharge history of li-ion batteries

Given all the advantages, Lithium-ion batteries can be cost-prohibitive for some businesses. Lithium-ions can also suffer damage at high temperatures or if they are stored with a full charge. These challenges may mean changes to your operational strategy to protect this investment.

Still wondering about the benefits of lead-acid vs lithium-ion forklift batteries? ITS Forklifts can help. From identifying the right battery to sourcing used or new equipment, we’ve got you covered. Our Forklift Experts is ready to help you find the right solution.